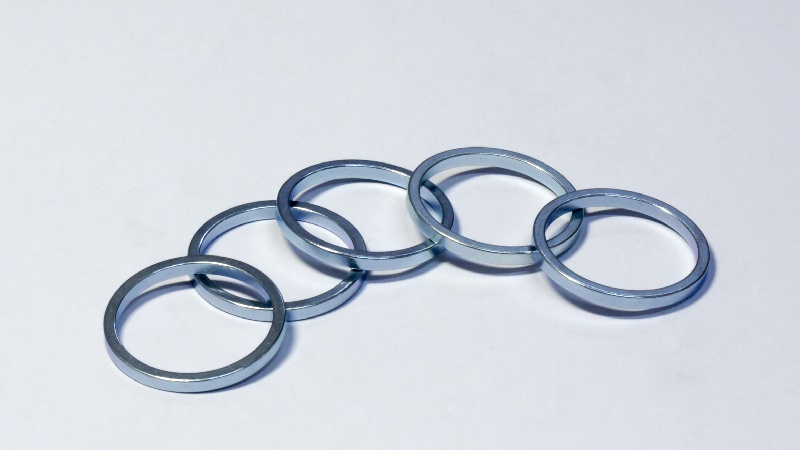

Neodymium Ring Shaped Magnets

Description

Reviews

Characteristic

Because of the different outer/inner diameter and thickness, the Ring magnets can be divided into ring, tube, disc. Two types (Diametral and Axial) of magnetization direction can be produced according to your design.

Appearance: Smooth and bright surface without burrs.

Advantages: Direct forming can save production cost and production time compared with square grinding/sleeving process.

Customized service

Grades: N30~N52, N30M~N52M, N30H~N52H, N30SH~N48SH, N25UH~N45UH, N28EH~N40EH, N28AH~N40AH

Size: According to customer's requirement, we can produce regular size and large size.

Magnetization modes: common magnetization and axial magnetization (thickness magnetization) and radial magnetization

Coating: conventional nickel-copper-nickel, blue-white zinc, phosphating/passivation, epoxy (phosphating, nickel-copper, nickel-copper-nickel base); other special coatings can also be provided: Teflon, gold plating, silver plating, Perrin, aluminium coating (new coating)

Application

Mainly used in all kinds of high-efficiency, energy-saving motors: high-speed motors, high-temperature motors, etc.

Other fields: packaging, bags, safety systems, magnetic separators, magnetic resonance imaging, medical industry, special door locks, filters and filters, sensors, loudspeakers, microphones/ear brushless motors, micro-motors, VCM (voice coil motor), magnetic coupling, magnetic suckers, magnetic tools, etc.