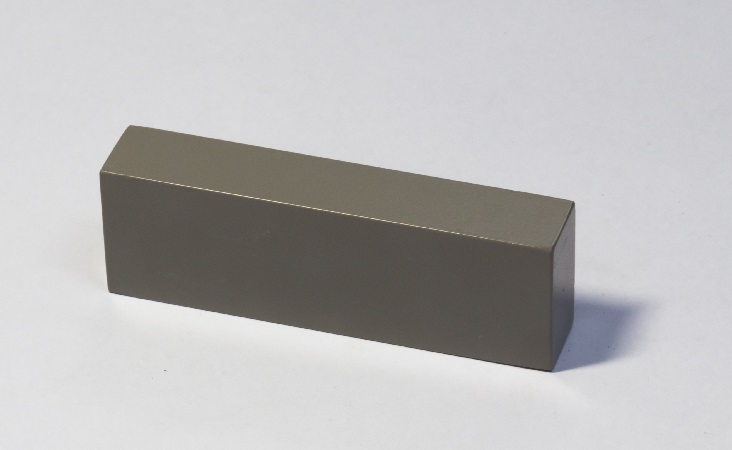

Epoxy Coated Neodymium Magnets

Description

Reviews

There are usually two colors (black, gray) and three kinds (NICU+EP, NICUNI+EP, P+EP) of the epoxy coating. Good properties in insulated properties, insulation, resistance to the alkali, acid, solvent and mildew. They can work in strict electrothermal condition. Strong combined force between products and coating. Good corrosion resistance with SST 72hours.

Shape

block/cylinder/ring/sphere/tile/sector/cube, etc.

Grades

N30~N52, N30M~N52M, N30H~N52H, N30SH~N48SH, N25UH~N45UH, N28EH~N40EH, 28AH~N40AH.

Magnetization direction

According to customer requirements.

Main characteristics of Sintered NdFeB magnets

Sintered NdFeB magnets are formed by powder metallurgy. The magnetic properties of all grades are optimized by applying a magnetic field during the pressing operation, resulting in a preferred direction of magnetization (anisotropy). Our sintered NdFeB magnets have four different characteristics: high corrosion resistance and low temperature coefficient, large size or small size. Compared with ordinary brands, our new brands have excellent corrosion resistance and high working temperature.

Applications

Safety systems, magnetic separators, magnetic resonance imaging, medical industry, special door locks, filters and filters, sensors, speakers, microphones/headphones, high performance motors, brushless motors, micro motors, servo motors, VCM (voice coil motor), automobiles, magnetic coupling, magnetic suckers, magnetic toys, magnetic tools, etc.